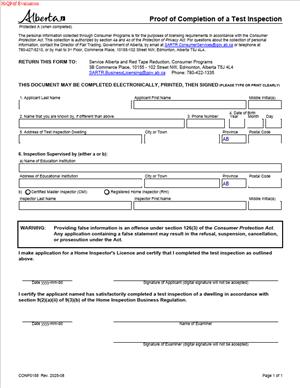

CONP0158 – Proof of Completion of a Test Inspection

Fill out nowJurisdiction: Country: Canada | Province or State: Alberta

What is a CONP0158 – Proof of Completion of a Test Inspection?

A CONP0158 – Proof of Completion of a Test Inspection is an official form used to confirm that a required test and inspection has been completed on a building system, component, or utility service. In Alberta, you use this form to show that the work you did under a permit has been tested, inspected, and meets the applicable code, standard, or permit condition. It helps the municipality, regulator, or owner verify that the work is compliant and safe to put into service.

You will most often see this form during the close-out of a permit or commissioning of a system. It can apply to life safety systems, utilities, equipment, and building services. Common examples include fire protection systems, gas piping pressure tests, plumbing systems, electrical protective devices, emergency lighting, elevators and lifts, HVAC and ventilation, backflow prevention assemblies, boilers and pressure equipment, and water mains or services. The form records test parameters, results, and acceptance, and it identifies who performed the work and who witnessed it.

Who typically uses this form?

Licensed contractors, master trades, registered professionals, property owners, developers, property managers, and tenant fit-out contractors. Safety codes officers and inspectors may request or reference it. Insurers and lenders may ask for it as part of risk reviews. Property managers may retain it in the building’s compliance file.

You need this form when a code, permit, or inspection condition requires proof of a test. It provides a clear record that you completed the required steps and the system passed. Many municipalities will not schedule a final inspection or grant occupancy until you submit this proof. Utilities often require proof before releasing or reconnecting a service. Owners and landlords may require it before accepting turnover of a space or system from a contractor.

Typical usage scenarios

- New builds

- Renovation close-outs

- Tenant improvements

- Recommissioning after repairs

- After a sprinkler hydrostatic test and alarm verification in a new retail unit.

- To show that a residential gas line held pressure before meter set.

- An annual backflow assembly test for a restaurant.

- To confirm a water main chlorination and bacteriological test in a subdivision.

- In each case, the form is the concise proof that the test occurred, the results met requirements, and a qualified person signed off.

The form format is straightforward. It identifies the project and permit, describes the system and test, records the results, notes any deficiencies and corrections, and carries the signatures of the tester and, if required, a witness or safety codes officer. You attach supporting documents like calibration certificates, data logs, photos, and commissioning sheets as schedules. When complete, the form becomes part of the permanent record for the property, permit, or equipment.

When Would You Use a CONP0158 – Proof of Completion of a Test Inspection?

You use a CONP0158 when a required test and inspection has been completed and you need formal proof for the authority or owner. Think of it as the bridge between the technical work on site and the administrative close-out. If a permit condition states “provide proof of testing,” this is the form you submit. If an inspector asks for evidence of a test, this is what you present. If an owner needs a file-ready confirmation for their records, this form serves that purpose.

Here is how it plays out. You are a general contractor closing a tenant improvement. The fire alarm contractor completes verification, and the sprinkler contractor completes a pressure test and flow test. Before you book final occupancy, you collect the CONP0158 from those trades, with their test reports attached. You submit the forms to the municipality. They review and clear the outstanding conditions, and you get occupancy.

Consider a residential infill where you installed new gas piping. Before the utility sets the meter, you perform a pressure test using a calibrated gauge. You hold the pressure for the required duration with no loss. You complete the CONP0158 with the test parameters, gauge details, and result. You submit it with the permit number. The utility confirms receipt and proceeds with the meter set.

For a restaurant, the municipality requires an annual test of the backflow prevention assembly. Your certified tester conducts the test and records check valve and relief valve performance. You complete the CONP0158 and attach the tester’s log. The property manager files it for compliance and sends a copy to the municipality if required.

On the civil side, a developer commissions a new water main. The contractor conducts pressure testing, flushing, and chlorination, and collects bacteriological samples. Once results pass, you complete the CONP0158 and attach lab results and the chlorination log. The municipality accepts the main for service.

You also use the form after repairs or modifications. If you replaced sprinkler heads in an existing system, you may need to test and submit proof. If you upgraded an electrical service and completed protective device testing, you document it. If you serviced a standby generator and conducted a load test, you file the proof. Landlords often require this for base building systems before releasing a tenant space.

Typical users

- Owners

- Landlords

- Condominium corporations who need records for due diligence

- Tenants and business owners use it when they are responsible for fit-outs and service reconnections

- Licensed contractors and master trades use it to close permits

- Engineers and technologists use it to certify tests for systems they designed or supervised

- Property managers use it to keep compliance current across their portfolios.

In short, you use the CONP0158 whenever you must move from “we did the test” to “here is the official proof.” It is practical, repeatable, and expected by Alberta municipalities and regulators during project close-out and ongoing maintenance.

Legal Characteristics of the CONP0158 – Proof of Completion of a Test Inspection

The CONP0158 is not a contract between parties. It is a formal attestation used in a regulatory context. By signing it, you certify that you performed the specified test and that the results are true and accurate to the best of your knowledge. Because authorities rely on it to make safety and compliance decisions, it carries legal weight.

Is it legally binding? Yes, in the sense that it forms part of the official compliance record tied to a permit, inspection, or utility service. When you sign and submit the form, you create a document that the municipality or regulator may enforce against. False or misleading information can lead to penalties, permit suspension, mandatory rework, or discipline of licences. It may also expose you to civil liability if others rely on the form and suffer loss due to inaccuracy.

What ensures enforceability?

The form captures key identifiers that link the certification to the regulated work: the permit number, project address, system description, test standard or method, instruments used, test parameters, and the identity and qualifications of the person signing. It includes a declaration that you completed the test and that the results meet the applicable requirements. A signature and date anchor the certification to a point in time. Some authorities may require the signature of a qualified person with a specific credential. In some cases, a professional stamp or permit to practice number may be required. When an inspector witnesses the test, their name and badge or identification may be recorded. Attachments like calibration certificates and lab reports strengthen the record and help ensure acceptance.

General legal considerations apply. Only a qualified person should sign the form. Use your legal name or registered business name, and include your licence or ticket number when requested. Do not sign for work you did not perform or supervise. Keep accurate records and retain supporting documents for the retention period required by the authority or your contract. Protect personal information on the form and share it only with those who need it for compliance. If a form asks for a professional stamp, do not use a stamp unless you are authorized and the work falls within your scope. If you discover an error after submission, correct it in writing and provide an updated form or addendum. If the system fails a test, do not certify it as passed. Instead, record the failure, correct the deficiencies, and retest before submitting a passing form.

How to Fill Out a CONP0158 – Proof of Completion of a Test Inspection

Follow these steps to complete the form accurately and avoid delays.

1) Confirm the requirement and scope.

Review the permit conditions and any inspection notices. Identify which system or component needs proof of testing. Confirm the exact test required, the acceptance criteria, and whether an inspector must witness it. Clarify if a professional signature or stamp is required.

2) Prepare before the test.

Gather the latest drawings, specifications, and any commissioning plans. Verify that your test instruments are calibrated and within date. Keep calibration certificates on hand. Ensure access to the system, isolation points, drains, vents, and any temporary equipment needed, such as test pumps. Notify the owner, property manager, and neighbours if the test may affect them. If a municipal inspector will witness, book the appointment and allow enough time.

3) Perform the test.

Set up the system safely and follow the required method. Record test parameters in real time. Note start and end times, pressures, flows, voltages, temperatures, or other applicable values. Document any adjustments made. If a failure occurs, stop and correct deficiencies before retesting. Keep photos or screenshots if they help confirm the setup and results.

4) Gather identifiers for the form.

You will need the permit number, project address, building name or unit, and legal description if available. Collect the owner or permit holder name and contact details. Record the contractor’s legal name, licence number, and contact details. Identify the tester’s name, ticket or credential, and company. If a professional is involved, note the professional number and permit to practice if applicable. If an inspector witnessed the test, record their name and identification.

5) Complete the project information section.

Enter the project address, municipality, and postal code. Add the permit number(s) that relate to the tested system. For large projects, list the relevant sub-permit or discipline permit, such as plumbing, gas, or electrical. Include the tenant name and suite if the test is within a multi-tenant building.

6) Describe the system and test.

Provide a clear description of what you tested. For example: “Sprinkler system, Level 2 retail, wet system, hydrostatic test.” Or “Gas piping from meter to rooftop units, pressure test.” Or “Backflow prevention assembly, 2-inch RP, annual test.” Include equipment IDs, serial numbers, model numbers, and locations as needed. State the test method in plain language. Include the acceptance criteria in simple terms, such as “No pressure loss for test duration” or “Valve closed tight with acceptable differential.”

7) Record test parameters and results.

Enter the values that matter. Include initial and final readings, duration, flows, voltages, temperatures, or other key measures. Note the instrument type, range, and calibration date. If applicable, list the fluid medium, test pressure, and temperature. If you have a data logger or lab report, reference it and attach it as a schedule. State the outcome as pass or fail relative to the acceptance criteria. Avoid vague language. Be specific and complete.

8) Note deficiencies and corrective actions.

If you found deficiencies, list them briefly. State how you corrected them and the date you retested. If the system passed after rework, make that clear. If certain minor items remain open but do not affect the test, identify them and explain the plan to close them. Do not certify a pass if a critical deficiency remains.

9) Identify parties and roles.

Confirm who is the permit holder and who performed the test. If different, make both clear. Identify the owner or owner’s representative. For tenant improvements, identify the tenant where helpful. If a professional directed the test, name them and their firm. If an inspector witnessed the test, show that in the witness section.

10) Complete the declaration and signatures.

Read the declaration carefully. It will state that you completed the test and that the information is true. Enter your name and title. Include your licence, ticket, or professional number as requested. Sign and date the form. If a professional stamp is required, apply it in the designated area. If a witness signature is needed, have the inspector or owner’s representative sign and date. Ensure all signatures are legible and dates are consistent.

11) Attach schedules and supporting documents.

Include all relevant attachments as schedules. Typical schedules include:

- Calibration certificates for gauges and meters used.

- Detailed test reports, logs, or trend data.

- Photos of the setup and gauge readings.

- Lab results for water quality or similar tests.

- Commissioning checklists and start-up sheets.

- As-built sketches or marked-up drawings showing test sections and isolation points.

- Manufacturer data sheets if needed for acceptance.

Label each attachment clearly and reference it in the form (for example, “Schedule A: Gauge calibration certificate”). Ensure file names are clear if submitting electronically.

12) Review for accuracy and completeness.

Check every field for accuracy. Confirm permit numbers, addresses, and dates. Verify that names match licences and business registrations. Ensure that numbers align (for example, test pressure on the form matches the report). Catching small errors prevents rejection and rework.

13) Submit the form.

Follow the submission instructions given by the municipality, regulator, or owner. You may upload the form and attachments to a permit portal, email them to a designated address, or provide paper copies at a counter. If there is a deadline tied to inspection or occupancy, submit early. Keep proof of submission.

14) Retain records.

Store a copy of the signed form and all attachments. Keep records for the required retention period. Owners and property managers should file the form in the building compliance records. Contractors should keep it with the project file. If warranty or service obligations apply, ensure your service team has access.

15) Handle revisions or additional tests.

If conditions change, or an inspector requests further testing, complete a new form or an addendum. Reference the original submission and explain the new scope. Avoid overwriting the original if it has already been accepted. Maintain a clear audit trail.

Practical tips

- Use black or blue ink on paper forms, and avoid pencil.

- Type entries on digital forms for clarity.

- Spell names correctly and use legal names.

- Do not leave required fields blank; use “N/A” only where it truly does not apply.

- Make sure your test instruments are readable in photos if you attach them.

- If your test spans multiple days, document each segment and explain why.

- If the system is part of a phased turnover, identify the phase or zone clearly.

Finally, match your form to the regulatory expectation. If the authority expects a specific format or includes prefilled fields for a given system, use that version. If they require a particular wording in the declaration, do not alter it. If they require witnessing, do not conduct the test without the witness unless you have written authorization. Your goal is a clean, defensible submission that an inspector can accept without follow-up.

Legal Terms You Might Encounter

- Authority Having Jurisdiction refers to the body that reviews your form. It could be a city, a regional office, or a delegated agency. On this form, the AHJ is the recipient and reviewer. You will submit the form to them, not to a private party.

- Permit Holder means the person or entity named on the permit. This is often the contractor or the owner. On this form, the permit holder is typically responsible for submission. They also carry responsibility for accuracy.

- Test Inspection is the verification that a system meets code and design. It uses a defined test method and threshold. This form records that the test was done and passed. It confirms the system is ready for service or for the next step.

- Witness of Record is the person who observed the test. This could be an inspector, owner’s rep, or qualified third party. On this form, the witness confirms the method and outcome. Their signature supports the form’s credibility.

- Attestation is your sworn statement that the details are true. It appears near the signature block on this form. When you attest, you confirm the test occurred as recorded. You also accept accountability for the statements made.

- Deficiency means a non-compliant or failed item found during the test. It could be a leak, a device fault, or a documentation gap. On this form, you must list each deficiency. You should also state how you corrected it or plan to.

- Corrective Action is what you did to fix a deficiency. It can be a repair, recalibration, or a replacement. This form should show the corrective action taken. It should also note the date and who performed the work.

- Re-test is a follow-up test after a deficiency fix. Many systems need a clean pass after correction. Use this form to record the re-test outcome. If the form only records passes, attach the failure record as well.

- Calibration Certificate proves your test instruments were accurate. It includes the instrument ID and expiry date. On this form, you often cite the instrument details. You then attach the calibration proof to support your results.

- Record Retention is how long you must keep the form. Retention rules can come from contracts, codes, or policies. Keep this form and attachments for that period. You may need them for audits, renewals, or incident reviews.

FAQs

Do you need to attach the test data?

Yes. Attach raw results, logs, or printouts. Include values, durations, and thresholds. Add diagrams that show test points. Include photos when they add clarity. Cite the instrument model and serial number. Provide calibration proof. Your attachments should let a reviewer replicate the logic and confirm the outcome.

Do you need a professional engineer’s seal?

Not always. Some systems do not need a seal for this proof. If design, code, or permit conditions require one, include it. Check the permit notes for any seal requirement. If in doubt, ask the project’s engineer of record. Do not apply a seal unless you are authorized to do so.

Do you have to submit the form by a deadline?

Yes, in practice. Submission often ties to occupancy, energization, or commissioning. Many permits set a final deadline. Some AHJs set timelines after inspection. Submit promptly after a pass. Late submission can delay occupancy or energization. Plan your testing to avoid deadline pressure.

Can you submit one form for multiple systems?

Usually no. Most AHJs want one form per discrete system. That could be per floor, zone, riser, or device type. Separate forms reduce confusion and speed review. If your scope is small and uniform, ask about bundling. When in doubt, use separate forms.

Do you need a witness signature?

If a witness attended, yes. A witness signature adds weight. Some AHJs require it for specific tests. If no witness attended, document that fact. Make the tester’s attestation clear and complete. Attach time-stamped photos and logs to support the claim.

Can you sign and submit electronically?

Often yes. Many AHJs accept digital signatures and uploads. Use a verifiable digital signature, not just typed text. Ensure the signing date is correct. Combine attachments into a clear, readable package. Follow the portal or email size limits. Keep a full copy of what you sent.

What happens if the test fails?

Document the failure and every deficiency. Record the corrective actions taken. Schedule and complete a re-test. Attach both the failure record and the pass record. Submit the proof only when the system passes. If the AHJ needs interim notice, send a progress update.

Do you have to keep the original form?

Yes. Keep the original or a certified true copy. Store all attachments with it. Follow your retention policy. Keep both digital and paper copies if possible. Protect sensitive information. Make the file easy to retrieve for audits or renewals.

Checklist: Before, During, and After the CONP0158 – Proof of Completion of a Test Inspection

Before signing: gather information and documents

- Permit number and project name.

- Site address and legal location description.

- System type and scope covered by this test.

- Drawing numbers and revision dates.

- Test procedure used and acceptance criteria.

- Test start and end times and total duration.

- Environmental conditions during the test.

- Test medium and pressure or load, as applicable.

- Instrument make, model, serial number, and range.

- Calibration certificates for each instrument.

- Names and roles of all attendees and witnesses.

- Photos or screenshots with timestamps.

- As-built markups showing test points or zones.

- Deficiency list and corrective actions taken.

- Re-test records, if any.

- Contact details for the signatory and permit holder.

- Any required seals or stamps, if applicable.

- Submission method and any portal reference numbers.

- Internal approval from your firm, if required.

During signing: verify accuracy and completeness

- Confirm the permit number matches the permit card.

- Check the site address and unit numbers.

- Ensure the system description matches the tested scope.

- Verify dates and times are correct and consistent.

- Confirm pass/fail boxes reflect the final outcome.

- Check the test parameters match your data logs.

- List each deficiency with a clear correction note.

- Include re-test data if corrections were made.

- Ensure all required fields are filled, not left blank.

- Confirm the signatory name and title are accurate.

- Use the correct sign date and location.

- Apply seals or stamps only if required and authorized.

- Have the witness sign, if attendance occurred.

- Initial any corrections or strike-throughs.

- Check legibility of names, numbers, and notes.

- Number your attachments and reference them on the form.

- Ensure page totals and attachment counts are correct.

- Save a PDF that preserves signatures and images.

After signing: file, notify, and store

- Submit the form to the AHJ using the required method.

- Confirm receipt and obtain a submission reference or stamp.

- Notify the owner, permit holder, and prime contractor.

- Share a copy with the facility manager or operator.

- Update the commissioning log and turnover checklist.

- File the form with the as-built drawings and O&M manuals.

- Record the test in your asset registry, if applicable.

- Store calibration certificates with the test package.

- Set reminders for any follow-up inspections or re-tests.

- Securely archive the full record per retention policy.

- Document any conditions of acceptance noted by the AHJ.

- Track and close out any requested clarifications.

Common Mistakes to Avoid

- Using the wrong permit number or address can derail review. The consequence is rejection or delay. Don’t forget to match the permit card exactly.

- Leaving out instrument details reduces trust in your results. Reviewers may question accuracy. Include model, serial, and calibration proof.

- Recording only “pass” without the test parameters is insufficient. You risk a request for more data. State the method, thresholds, and readings.

- Submitting one form for several unrelated systems causes confusion. You may face resubmission. Use one form per system or zone.

- Missing signatures or backdating undermines credibility. Your form can be voided. Sign on the actual date and have all required parties sign.

- Attaching unreadable scans or photos wastes time. Reviewers may reject the package. Check clarity, orientation, and resolution before sending.

- Ignoring deficiencies found during the test is risky. It can lead to enforcement action. Document fixes and show the successful re-test.

What to Do After Filling Out the Form

- Submit the signed form with all attachments to the AHJ. Use the method they specify. Keep the submission confirmation.

- Share the final package with project stakeholders. Send it to the owner, permit holder, and operator. Include any conditions noted by the AHJ.

- Update your commissioning and turnover records. Place the form in the closeout binder. Add it to the digital project vault.

- If the AHJ requests changes, respond quickly. Prepare an amended form if facts change. Mark it as an amendment and explain the change.

- Schedule any follow-up inspections or re-tests. Note the dates and responsibilities. Keep the plan visible to the team.

- Integrate the results into maintenance planning. Add test dates and intervals to the maintenance system. Track any expiry dates for calibrations.

- Prepare for final approvals linked to this proof. This may include occupancy or energization steps. Coordinate dates to avoid delays.

- Archive the full test package securely. Include the form, data, photos, and certificates. Set retention reminders per your policy.

- If issues arise later, use this file as your record. It will support audits and incident reviews. Ensure anyone who needs it can retrieve it fast.

Disclaimer: This guide is provided for informational purposes only and is not intended as legal advice. You should consult a legal professional.